Why the Molded Vacuum Interrupter (MVI)?

Liquid-filled distribution class transformers, larger than 3000 kVA, are a challenge to protect using conventional transformer fusing. Fuse selection and coordination with protection is set at the time the transformer is manufactured and is not resettable. If an overload occurs causing the fusing to open, extensive outage time will be incurred to replace internal fusing if the event is outside the transformer.

With the advent of the Molded Vacuum Interrupter (MVI), transformer OEMs can properly protect transformers from an overload event or network from a transformer fault. MVIs are resettable after clearing the overcurrent event, and coordination with upstream protection can be adjusted should the protection scheme change and/or the transformer be relocated within the network. The MVI can also act as a load break switch to take the transformer off the network.

Externally mounted MVIs are an economical solution when compared to under oil solutions as they do not require additional transformer footprint to accommodate internal dielectric clearances, nor do they rely on dielectric integrity of the transformer fluid for proper operation. External mounting means ease of access should there ever be a reason to service. To that extent, the MVI has been tested to clear up to 2000 faults – which would be far more than expected over the useful life of the transformer. So, for all intents and purposes, the MVI is a maintenance-free solution. Solid dielectric dead front insulation construction leaves no exposed live or energized parts at the interrupter. Proven EPDM rubber as the solid dielectric medium is a time-tested industry workhorse for over 50 years.

MVI Application Ratings:

- Up to 10,000 kVA

- 35kV – 150kV BIL primary voltages

- 600A continuous

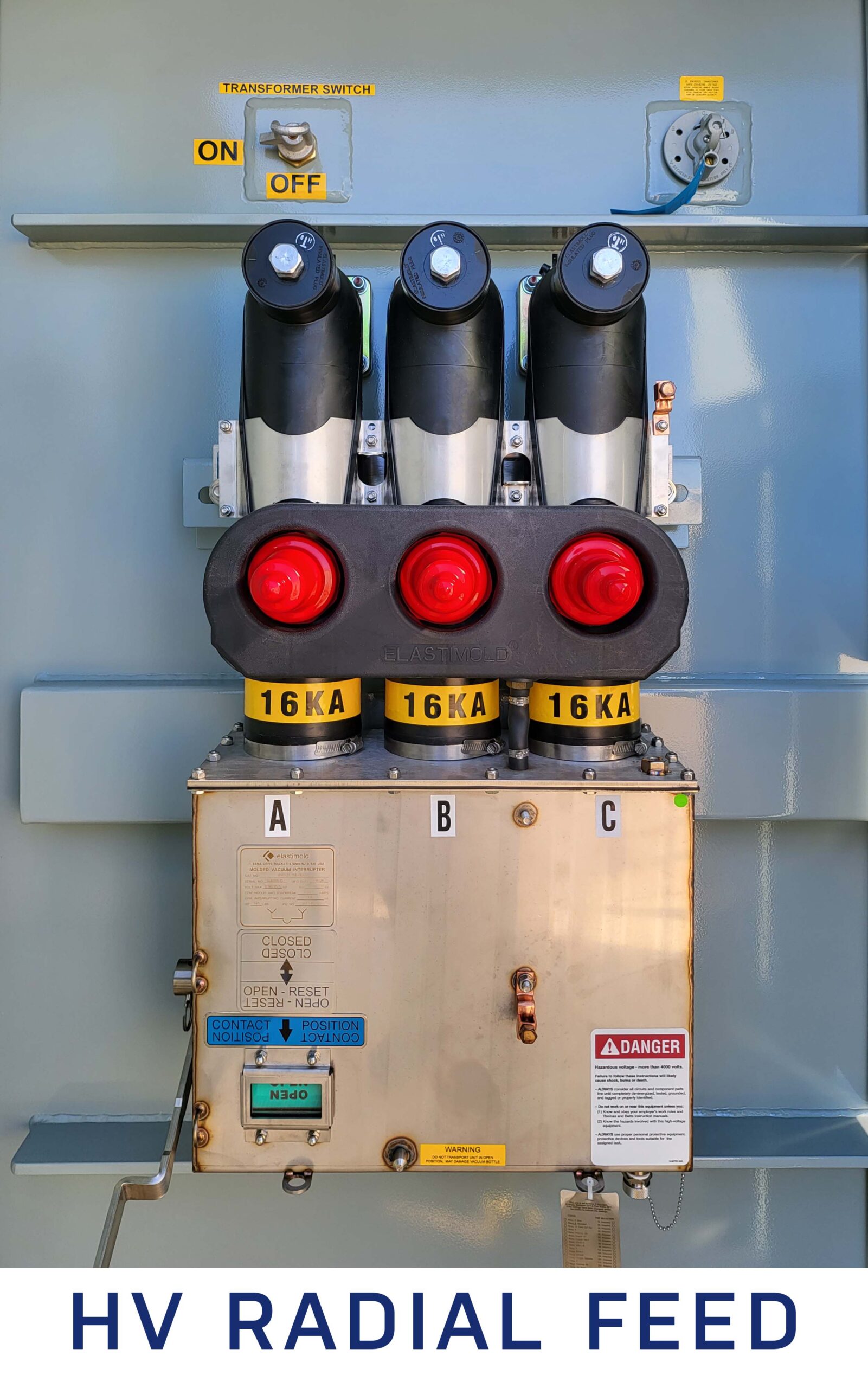

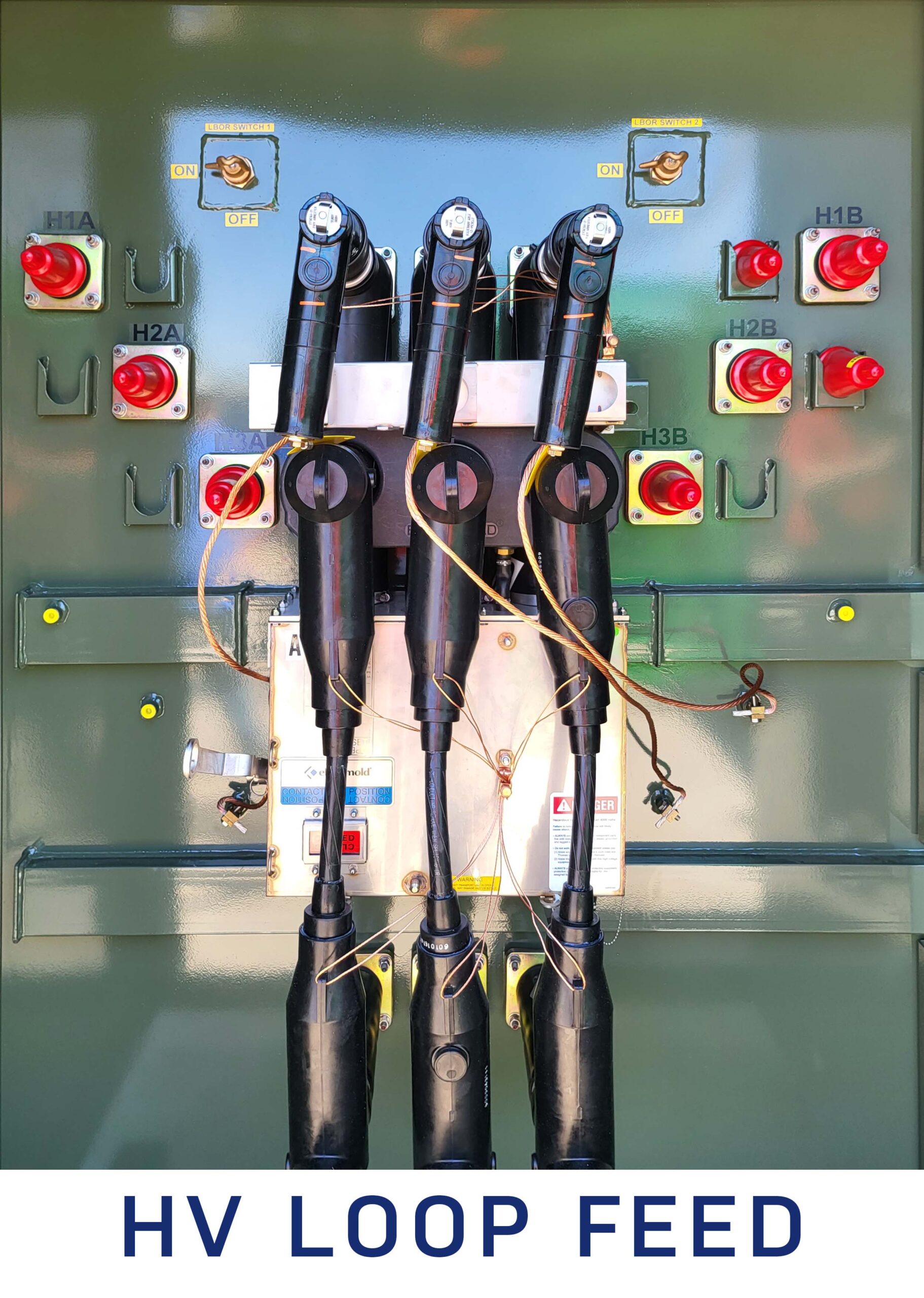

- HV radial or loop feed arrangements

- Padmount or substation design

- Fault Interruption Ratings

- 12.5kA Standard

- 16kA, 20kA at 15kV Optional

- 25kA at 38kV Mag Actuated

- Fault Close Rating – 20kA Symmetrical Momentary

The MVI is designed for submersible applications in underground vaults, which makes it suitable for transformer installations exposed to a variety of environments.

MVI Characteristics:

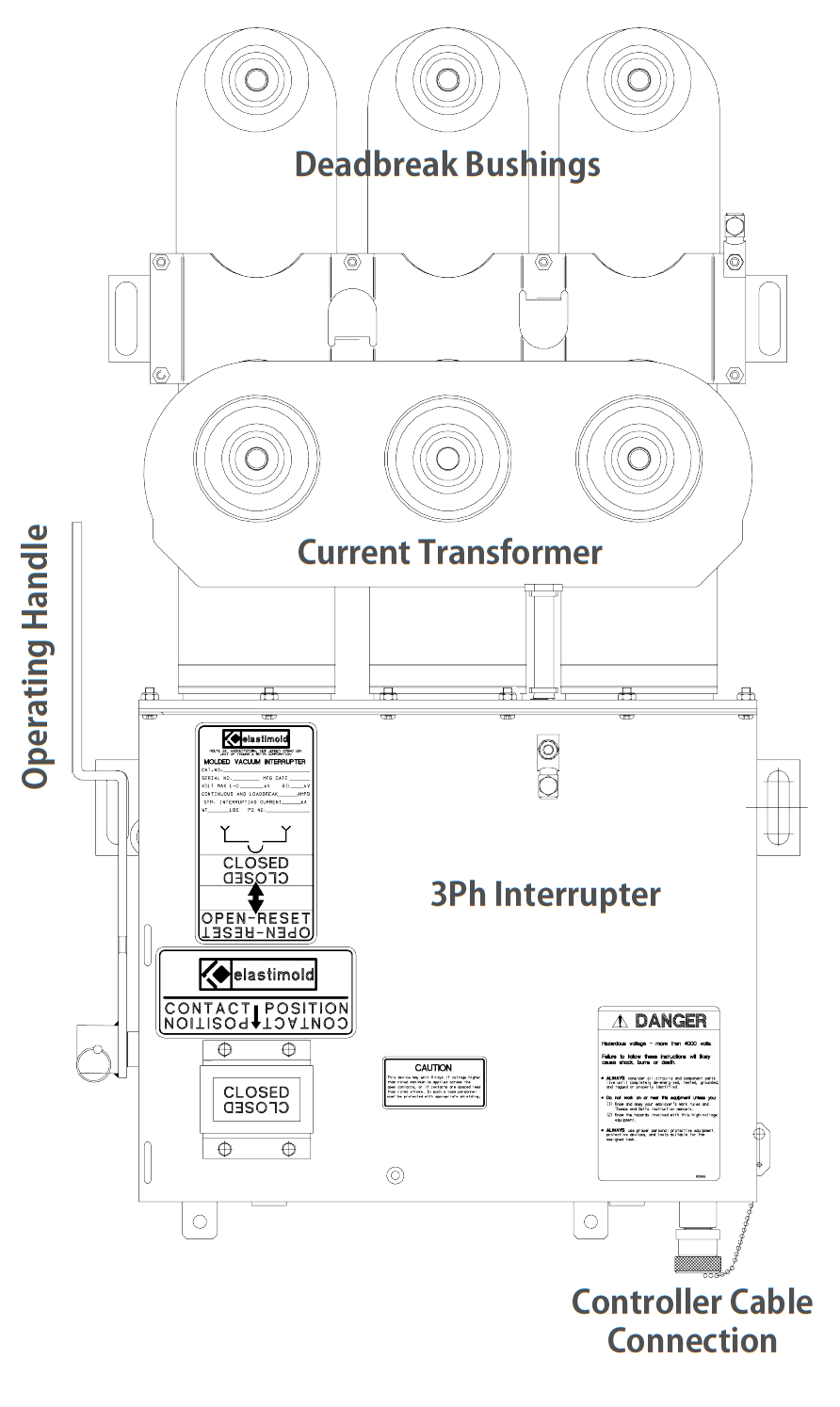

- Spring energy closed, stored energy opening operation – capable of making, carrying, and automatic interruption at 12,500 amps symmetrical.

- Trip-free mechanism preventing the possibility of holding the mechanism closed under a faulted circuit.

- Self-powered – including current sensing and electronic control.

- Control module (Model 80) is field programmable with a wide range of Time Current Characteristics (TCC) curves and trip settings that provide basic overcurrent trip capability.

- TCC curves provide predictable tripping for ease of coordination with upstream and downstream protection devices. The controller monitors the circuit conditions and sends a signal to the MVI tripping mechanism if the programmed parameters are exceeded.

- Proven technology with over 20 years of interruptor experience and over 50 years of EPDM experience in field applications.

MVI Features:

- Deadfront construction for safer operation utilizing common IEEE 386 standards for separable connectors & bushing interfaces.

- Integrated current sensing for electronic trip control.

- Self-powered controls so no battery or external power is required.*

- Trip setting & TCC curves are field-programmable while the unit is energized.

- Suitable for all environments being a sealed system with EPDM rubber as the solid dielectric.

- Load break & fault current interrupted by hermetically sealed vacuum bottles.

- Components are maintenance-free & require no gas or dielectric fluid for operation.

- Manual reset mechanism with lineman hot stick provisions.

- Spring energy mechanism initiated by electronic trip – maximum 3 cycles interrupting time.

MVI Options:

- 600A or 200A interface.

- Motor drive for remote operation & position indication.

- Direct interface for voltage sensors & surge arresters.

- Visual break indication.

- SEL relay to provide an additional level of protection to the interrupter & transformer such as overcurrent/under-voltage, over-pressure trip, or thermal trip protection.